Category

High Speed Endless Take up Dobby Shedding Shuttleless Wire Mesh Weaving Machine

Overview Package Size 240.00cm * 220.00cm * 120.00cm Package Gross Weight 2500.000kg The machine adopts PLC programmable

Overview

This machine is mainly used for the weaving of precision metal steel of special screen printing grade, which can meet the technical requirements required for screen printing applications in the electronics and optoelectronics industry market

Detailed Photos

After Sales Service

We can send our technicist to the buyers' place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees: free

The training fees: First 7days is free , after that USD100/day for each technical

The numbers of technical persons: one technical person per machines at most.

The fees :round-trip tickets, accommodation etc, are all in buyers' account.

During the maintenance period:the parts damaged non-artificially will be provided free of charge. If buyers need the technicians,we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

After the maintenance period:If buyers need the machine parts, we will provide it as our cost. If buyers need the technicians, we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

Auxiliary machineMore products

Basic Info.

| Model NO. | BX |

| Customized Machine | Available |

| Identification | CE,ISO |

| Old or New | New |

| After Sales Service | Yes |

| Computerized | Computerized Numerical Control |

| Speed | 60-120times/Minute |

| Weaving Width | 1300mm,1600mm,or Customozed |

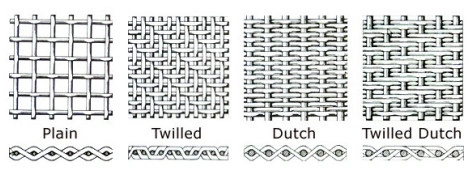

| Weave Pattern | Plain,Twilled,Dutch |

| Electronic Cabinet Highth | 1600mm |

| Wire Diameter | 0.02mm-0.12mm |

| Weight | 2500kg |

| Mesh Count | 40-600mesh |

| Transport Package | Naked Cargo |

| Specification | 2400mm*2900mm*1200mm |

| Trademark | APM |

| Origin | Hebei, China |

| HS Code | 8446309000 |

| Production Capacity | 2000 Pieces/Year |

Packaging & Delivery

Package Size 240.00cm * 220.00cm * 120.00cm Package Gross Weight 2500.000kgProduct Description

The machine adopts PLC programmable control system, through servo motor and turbine reducer control cloth take-up and warp let-off to achieve automatic mesh tension adjustment, so that the mesh precision is high, Which can be more accurate weaving 80-600 square mesh with the standard wire diameter and also weave up to 2600 Dutch mesh; The independent servo motor drives each piece of heddle frame to freely set the heddle frame sequence, the height and closing time to achieve smooth wire tension, and the diversification of braid patterns; The direct drive AC servo weft insertion can adjust the rapier return time and the length and time of the second pulling at will. The limit setting of the rapier belt not only effectively protects the rapier belt and head but also improves the safety factor of the rapier belt operation. The absolute encoder is used to prevent accidents and defects such as abnormal power failure, brake instability, and data loss resulting in the clamping of the rapier belt, making the operation more stable.This machine is mainly used for the weaving of precision metal steel of special screen printing grade, which can meet the technical requirements required for screen printing applications in the electronics and optoelectronics industry market

| Machine Type | BX |

| Weaving Width | 1300mm, 1600mm, 2000- 2500mm |

| Weaving Mesh Range | Square Mesh: 40-600(Mesh) Dutch Mesh: 2600(Mesh) |

| Warp/Weft Wire Range | Blow 0.30mm |

| Driver Way | Electromagnetic Brake Motor Driver, Variable frequency Speed Regulation |

| Heddle Frame | 2,3,4,5,6 |

| Shedding Mechanism | Aluminum heddle frame, 1.5KW AC Servo per frame. |

| Beating Mechanism | The crankshaft is a 65mm diameter, 45 (55) steel monolithic forging, and the slay (55 square steel) is made of carbon structural steel after heat treatment; |

| Weft Insertion | 2.3KW high performance AC servo motor direct drive, The guild wheel drive the carbon fiber rapier belt to do reciprocating weft insertion motion |

| Warp let-off System | Servo motor drive,electronic control wire tension feedback, double rear beam, negative swinging rear beam stabilizing mechanism |

| Cloth Take-up System | Servo motor drive, 3Pu coating beam unlimited cloth take-up mechanism, digital display weaving length |

| Control System | New weaving machine control system |

After Sales Service

Sale service:

Maintenance period: one yearWe can send our technicist to the buyers' place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees: free

The training fees: First 7days is free , after that USD100/day for each technical

The numbers of technical persons: one technical person per machines at most.

The fees :round-trip tickets, accommodation etc, are all in buyers' account.

During the maintenance period:the parts damaged non-artificially will be provided free of charge. If buyers need the technicians,we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

After the maintenance period:If buyers need the machine parts, we will provide it as our cost. If buyers need the technicians, we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

Auxiliary machineMore products