Full Automatic Deburring and Derusting Machine Stainless Steel Wire Drawing Wet Polishing Machine

Basic Info.

| Model NO. | ADV 508-Rr |

| Delivery Motor Power | 5.5 Kw |

| Lift Motor Power | 0.55 Kw |

| No.2 Motor Power | 22 Kw |

| Feed Speed | 0.5-5m/Min Frequency Speed |

| Machine Weight | 4300 Kg |

| Water Pump Power | 0.75 Kw |

| Available Thickness | 0.5-100mm |

| No.1 Motor Power | 30 Kw |

| Belt Size | 2200*1620 mm(or Customizable) |

| Available Width | 30-1600 mm |

| Product Name | Adv 508-Rr1600 Metal Finishing Machine |

| Transport Package | Wooden Packing |

| Specification | 2600*2500*2450 mm |

| Trademark | ADV |

| Origin | China |

| HS Code | 8401200000 |

| Production Capacity | 100 Sets/Month |

Product Description

Product Description

Tips:PLC sheet metal finishing machine with abrasive belt and roller brush

1.Used to remove longitudinal burrs from laser cutting, stamping and waterjet cutting workpieces.

2.The equipment can complete large burr rough grinding and surface brushed at one time. It is used for large surface sanding treatment to remove scratches and make the surface uniform, which can remove the oxide layer on the surface of the workpiece powerfully.3.The standard available width is 630mm, 1000mm, 1300mm, 1600mm, or customized.4.The deburring machine can be used in the wet process or dry process.

Machine Parameters

| Product name | ADV 508-Rr metal sanding machine for flat parts | ||

| Working width range | 30-630 mm | 30-1000 mm | 30-1300 mm |

| Available thickness | 0.5-100mm | ||

| Feed speed | 0.5-5m/min Frequency speed | ||

| Belt size | 1900*650 mm | 2000*1020 mm | 2200*1320 mm |

| Delivery motor power | 3 kw | 3 kw | 4kw |

| Total motor power | 35.1 kw | 49.45 kw | 58.45kw |

| Overall demension | 2200*1500*2450mm | 2350*1850*2450mm | 2500*2200*2450mm |

| Machine weight | 2000 kg | 2700 kg | 3800 kg |

Machine Parts

ADV 508-Rr metal sanding machine with abrasive belt and roller brush

>About ADV 508-Rr metal sanding machine with abrasive belt and roller brush, application laser, water jet cutting and punched parts,please tell us your material max width, then we can recommend the suitable size to you.

Oxide Layer Removal

Oxide skin occurs on metal and stainless steel when laser cutting, and it must be removed for subsequent coating processes or welding.

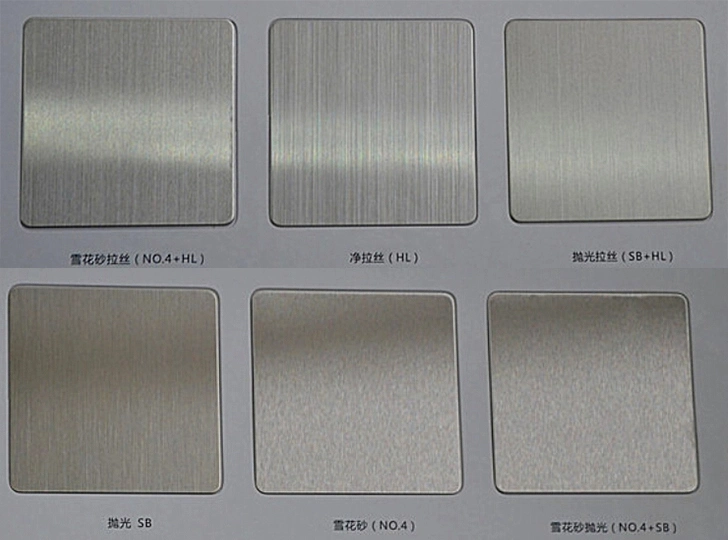

Pefect hairline finishing

A combination of finishing with abrasive belt station and roller brush station

Available model:

ADV 508-RRNo. 3 or no. 4 finishing with abrasive belts from grit 120, 180.

ADV 508-RPScotch-Brushed finishing with abrasive belt and polishing pad.

ADV 508-RrLong scratch hairline finishing with abrasive belt and roller brush.

ADV 508-RR SHEET METAL FINISHING MACHINEMore Time-saving!More Cost-saving!More stable and better performance!Consider Everything for Customers, Create More Value for Customers!

Machine Aplication

Application Materials:ADV 508-Rr Sheet metal finishing machine is suitable for stainless steel, steel, aluminium, copper, etc.

Application products:Sheet to Sheet or Coil to Coil.

Application Industries:ADV 508-Rr sheet metal finishing machine are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

We Support FREE Testing Samples for CustomersIf you have any questions about the sheet metal finishing machine or other related questions, please contact us withouthesitation.

FINISHING OF SHEET METAL PRODUCTS:This machine can be built to produce a variety of sheet metal finishes. Metal finishing is the last step in the manufacturing,that adds to the protection and aesthetics of the products. The most common finishes are decorative finishes as for instance a straight-line or a grain finish.These can be accomplished in finishing processes that use abrasive belts, polishing pad, roller brushes.

Company Profile

ADV is a new brand opened in the end of 2018, but the factory already has 25 years of designing and producing deburring machine, grinding machine and polishing machines. The original intention is to create a brand which is most reliable in China and most famous in the world. We made a plan to finish it within 5 years. We will take priority for all products we were and are selling out and best service for each order. We do believe in our original intention and keep moving to achieve it!

Anhui Advanced Grinding Tools Company has been adhering to the concept of excellent quality and reasonable price. We are committed to optimize the supply chain, strictly control the quality, supervise the production and debugging process of machines, and ensure the delivery of high-quality products to customers. In addition, we have experienced sales and service personnel to provide customers with high-quality pre-sale, after-sales and technical support services.The company actively explore foreign markets, advocate the business philosophy of integrity management, promote the development of customers is our driving force. Our products are exported to Europe, America and Southeast Asia.

* About Sheet Metal Finishing Machine Quality Control1, All-round quality control in the procurement process, all components used famous brands2, All machines can be traced back to the production batch, which is convenient for quality control and after-sales.3, Round after round of testing before delivery to ensure that the machines arrived without any possibility of problems.Packaging & Shipping

Ports:Shanghai Port / Ningbo Port / Customer Demand

Our Services

1, Overseas after-sales service is available.2, Two years warranty.3, Foundation drawings, manual book, electric wiring diagram, electric manual book, and maintenance book, etc. provided.4, We visit each country every year for free technical instructions.

Our overseas service photo show:

FAQ

Q: Do you have CE certification and other documents for customs clearance?

A: Yes, we have CE, Provide you with a one-stop service. At first we will show you and and after shipment we will give youCE/Packing list/Commercial Invoice/ Sales contract for customs clearance

Q: If we are interested in your machine, how do we choose?1. What is the max width of your product?2. What is the thickness range of your product?3. What is the material of your product?4. What is the thickness of most heavy burr?Please tell us, then we can recommend the suitable machine to you

Q: How about warranty?

A: 2 years quality guaranty. Lifetime technical support and consumables at the lowest price

Q: Do you have after sales support?

A: Yes, we have rich experience in handling after-sales issues via video or email. Meanwhile the engineers are available toservice overseas. We have agents in different countries too if you want local service or sample testing.